- The paper introduces FreeShell, a novel 4D printing technique that uses thermoshrinkage to self-assemble complex 3D triangle mesh shells.

- The methodology employs discrete flattening and optimized connector design to minimize distortion and ensure precise shape fidelity.

- Evaluation demonstrates low average error margins and robust performance across applications from medical devices to automotive components.

FreeShell: A Context-Free 4D Printing Technique for Fabricating Complex 3D Triangle Mesh Shells

Introduction

The paper introduces FreeShell, a novel 4D printing approach leveraging thermoshrinkage to fabricate complex 3D triangle mesh shells. In various industries where freeform thin-shell surfaces are utilized, traditional fabrication methods require extensive resources and custom molds, leading to increased costs and material waste. Moreover, while 3D printing can address some of these challenges, it typically involves extensive support structures and post-processing, thus limiting its effectiveness for manufacturing thin-shell surfaces. FreeShell addresses these issues by introducing a robust method that utilizes thermoshrinkable connectors. This approach simplifies fabrication while allowing for precise control of shell formation, independent of material properties and environmental conditions.

Methodology

FreeShell employs a combination of computational geometry and material science to achieve its goals. The technique begins with the input of a triangular mesh representing the target surface. Through a discrete flattening method, the 3D surface is transformed into a 2D layout of triangular tiles separated by shrinkable connectors. Upon heating, these connectors shrink, pulling the tiles together to approximate the 3D target shape.

Key Features:

- Thermoshrinkage Actuated Curvature: Connectors between tiles shrink upon heating, actuating the transformation into desired shapes.

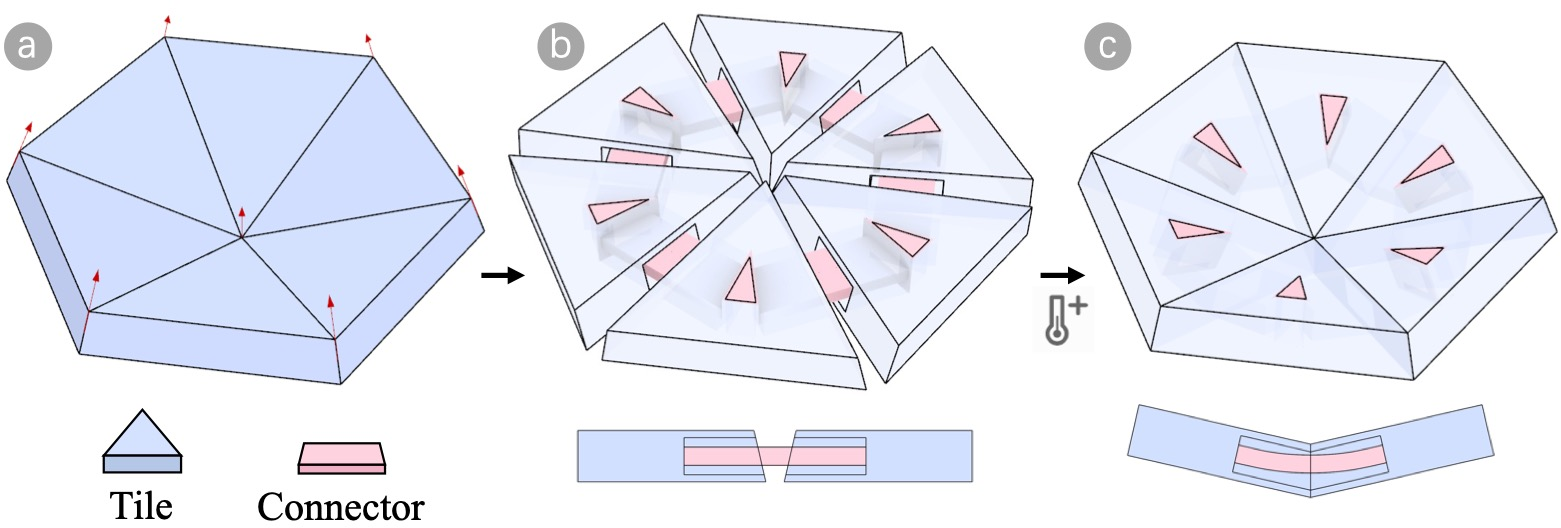

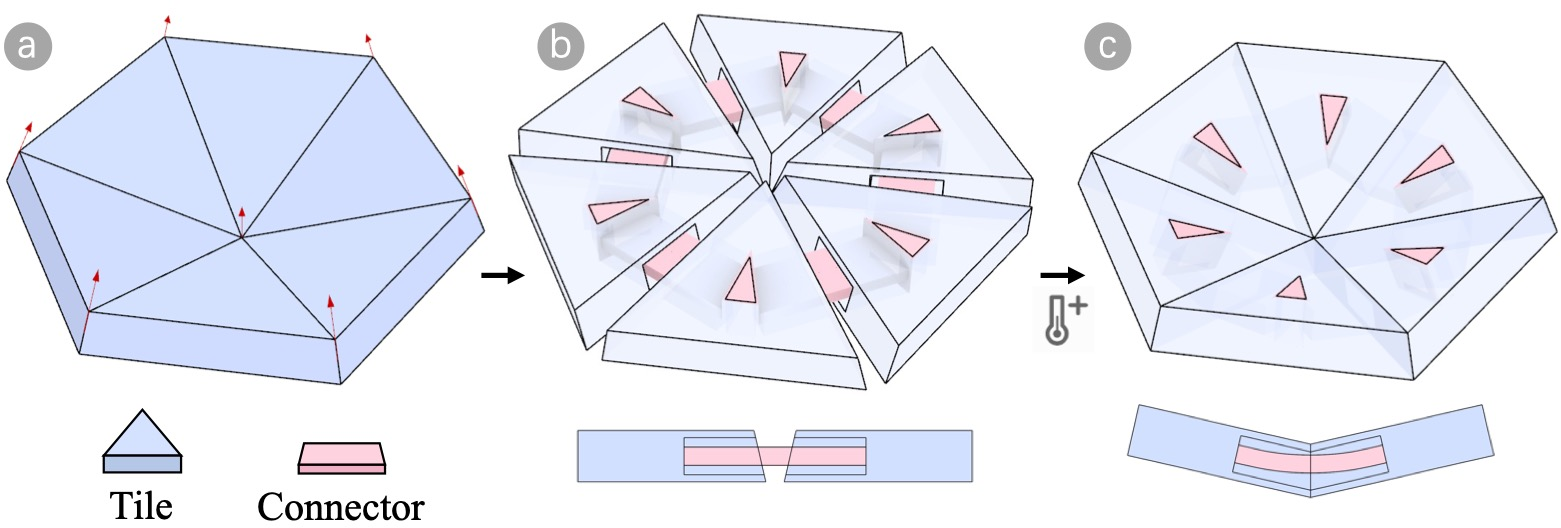

Figure 1: Basic idea of thermoshrinkage actuated curvature. The target shell consists of tiles that contain the curvature of the target shell (a). The flat plate consists of tiles and connectors (b). The connectors drive the tiles to form the target shell (c).

- Discrete Flattening: The optimization process to lay out the tiles addresses both geometric accuracy and ease of fabrication by minimizing distortion and ensuring non-intersecting 2D arrangements.

- Innovative Tile and Connector Construction: The design of connectors ensures adequate shrinkage force to achieve the target layout efficiently, with customized parameters to cater to varying conditions.

Implementation

The implementation involves several computational and practical steps. Initially, a conformal mapping process is applied to the target mesh, followed by algorithmic optimization to achieve desirable 2D layout properties such as rigid triangles, acceptable gap values, and shear avoidance.

Workflow Illustration:

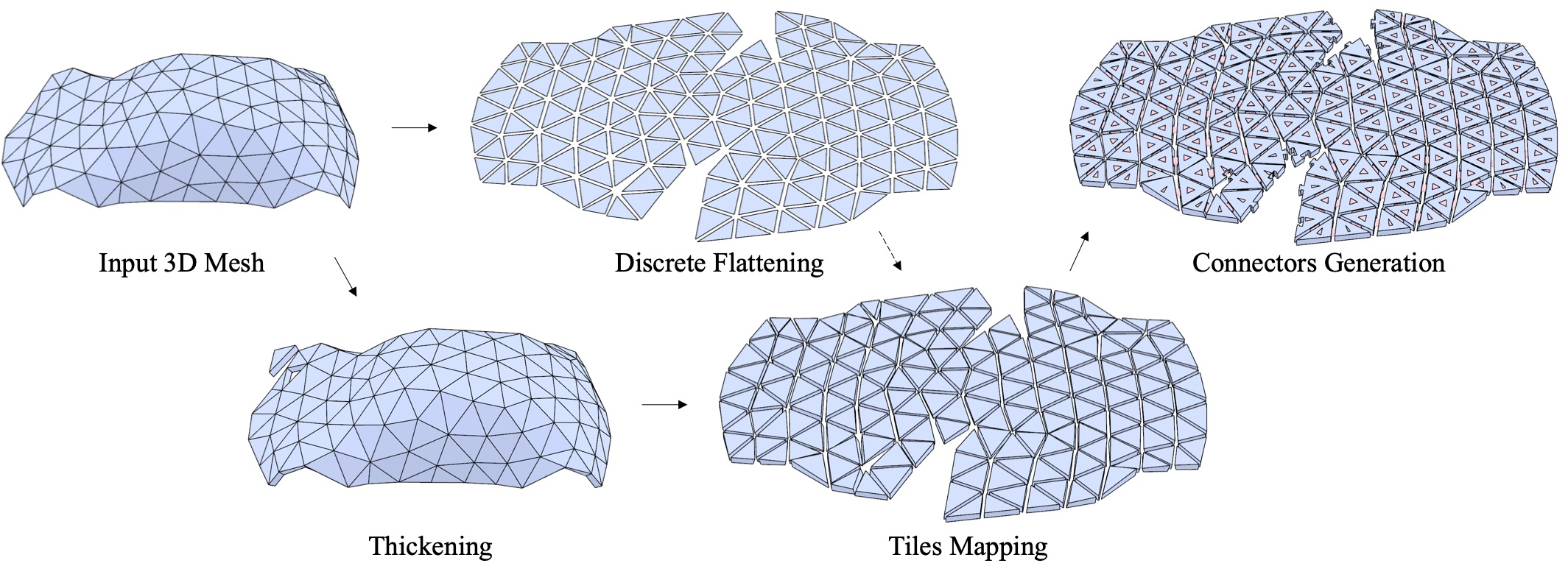

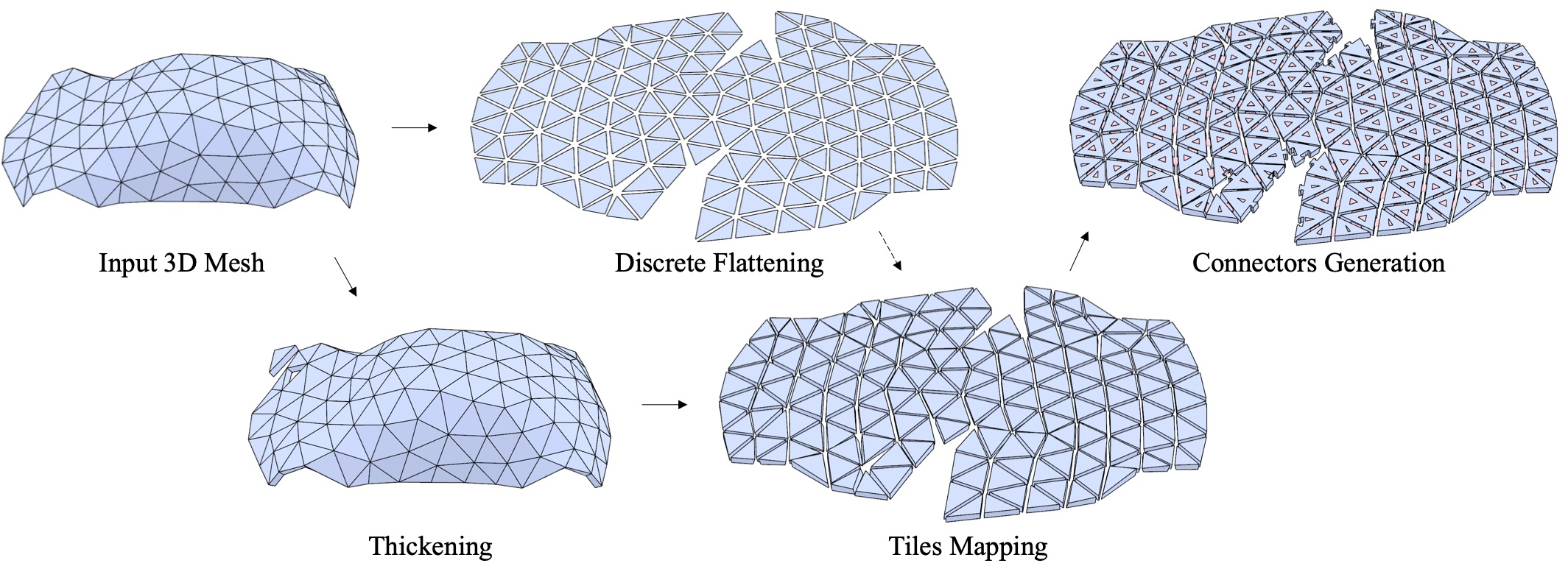

Figure 2: Computational design process of the flat plate. We input the target 3D mesh and the flat plate including tiles and connectors is constructed.

Optimization Process:

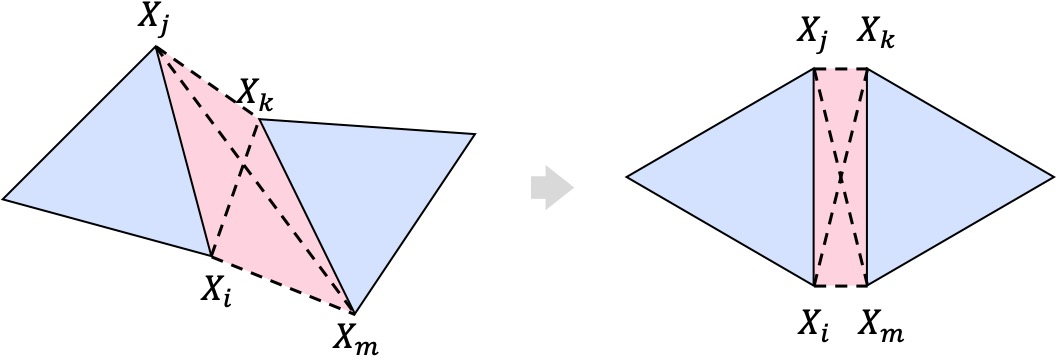

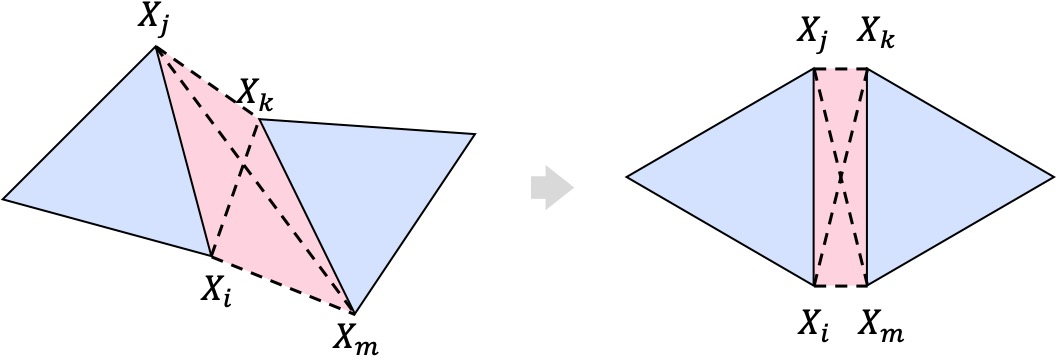

Figure 3: Shear avoidance: The fairness energy term aims to make the interior angles of the linkage as close to right angles as possible. Specifically, ∣∣Xi and ∣∣Xm represent the short edge lengths of the linkage.

Evaluation

The evaluation comprises extensive testing of various shell shapes and performance assessments:

- Accuracy: After the transformation process, numerical analysis of shape fidelity indicates average distance errors below certain thresholds.

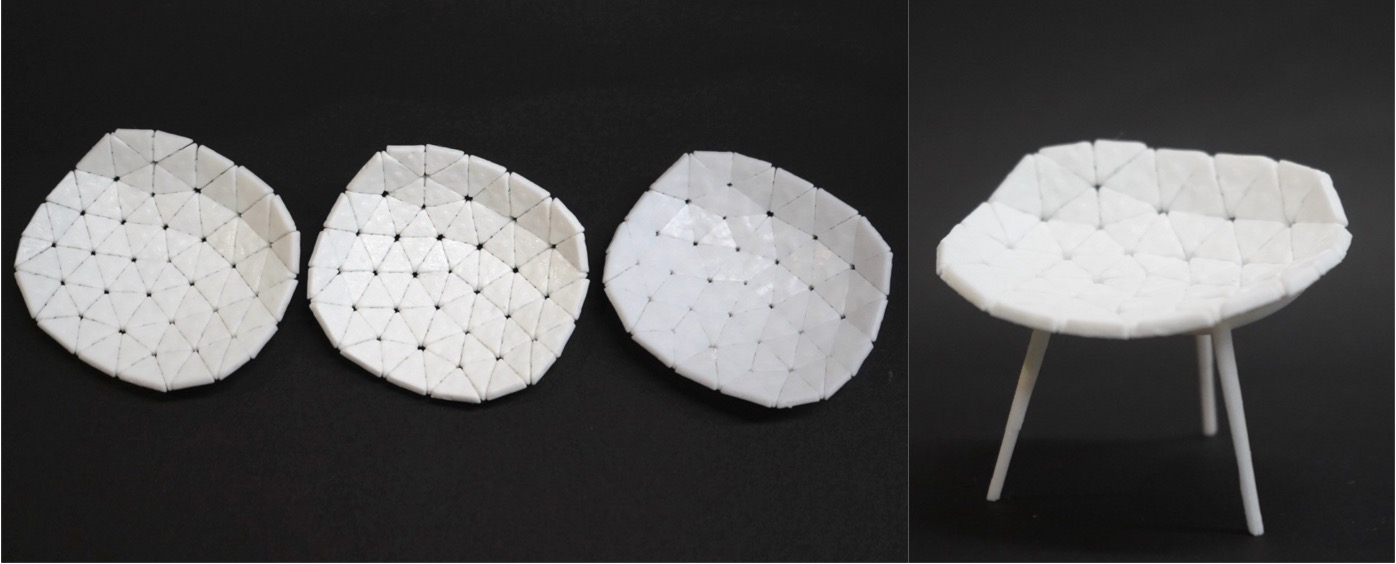

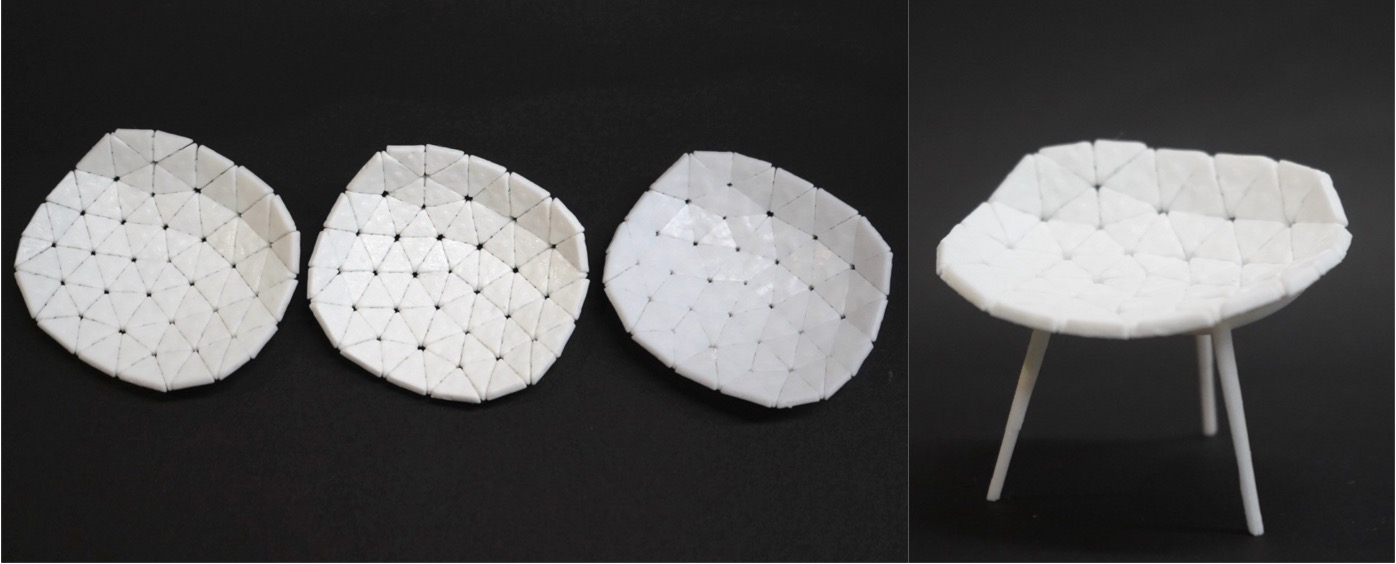

- Robustness: Using materials from different vendors and various shrinkage rates (Figure 4)

Figure 4: Similar fabricated results with different shrinkage rates, where these average values of the shrinkage rate are not less than 0.14 (0.14, 0.19, and 0.15, respectively). The deformation is completed in hot water at 75°C.

- Applications: The method has demonstrated success with a range of applications including medical devices, automotive components, and more intricate shapes. Practical examples include the creation of wrist and neck braces.

Figure 5: Applications of the medical supports. (a) The wrist brace is used to stabilize the wrist joint. (b) The neck brace is used to support the head.

Conclusion

FreeShell exemplifies significant advancements in the field of 4D printing by circumventing the traditional constraints associated with 3D shell fabrication. Its context-free approach enables reliable deployment of complex geometric shells without requiring stringent control over varied conditions, presenting potential advancements in scalable production of freeform structures. Future work may address further optimization methods, automatic interlocking of structures, and advancements in interactive design processes. The resulting shells maintain mechanical stability, making them applicable for structural and ergonomic applications across multiple domains.