- The paper presents a novel simulation-rendering pipeline that combines 3D Gaussians with dual-component viscoelastic and elastoplastic models to capture complex material dynamics.

- It leverages Score Distillation Sampling from video diffusion to optimize physical parameters, achieving high-fidelity animations as validated by metrics like PSNR, SSIM, and VMAF.

- Ablation studies demonstrate that both the elastoplastic and viscoelastic components are essential for accurately simulating realistic material behavior.

Physics3D: Learning Physical Properties of 3D Gaussians via Video Diffusion

Introduction

The paper "Physics3D: Learning Physical Properties of 3D Gaussians via Video Diffusion" introduces a novel approach to modeling the physical properties of 3D objects. Traditional 3D generative models emphasize surface attributes while neglecting the inherent physical properties that dictate object dynamics. Physics3D advances this field by integrating a viscoelastic material model into a simulation-rendering pipeline, allowing for the simulation of a wide range of materials. The framework leverages video diffusion models to distill physical priors, thereby enhancing physical accuracy in virtual environments. This essay explores the methodological intricacies and implementation of this approach.

Methodology

Unified Simulation-Rendering Pipeline

Physics3D is centered on a simulation-rendering pipeline that utilizes 3D Gaussians to represent objects, which are then simulated using the Material Point Method (MPM).

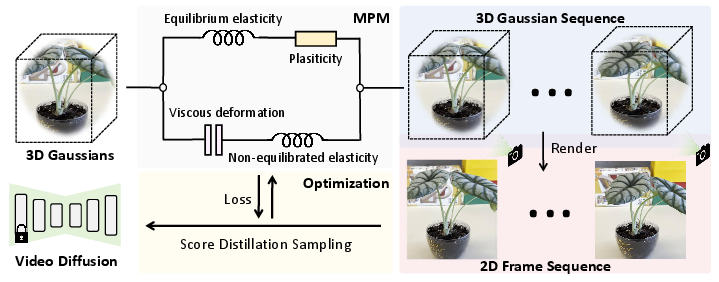

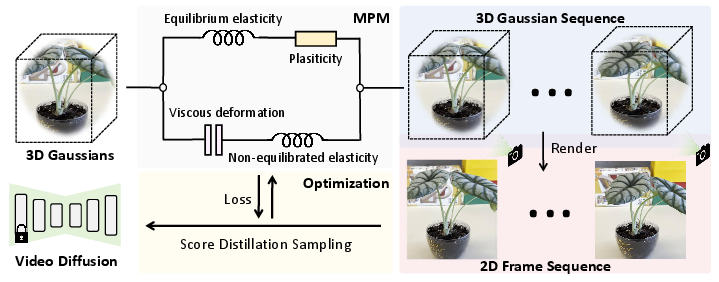

Figure 1: Physics3D is a unified simulation-rendering pipeline based on 3D Gaussians, which learn physics dynamics from video diffusion model.

This dual-component pipeline distinguishes between elastoplastic and viscoelastic properties, calculating stresses separately before combining them. This method supports extensive material simulations, capturing dynamic scene evolution and producing video frames through fixed viewpoint rendering.

Figure 2: Pipeline of Physics3D. Simulation uses the MPM with elastoplastic and viscoelastic components, followed by rendering and optimization via SDS.

Material Point Method with Viscoelasticity

MPM forms the backbone of Physics3D, discretizing materials into particles whose interactions model physical effects. The novel feature of this implementation is the dual-component stress calculation. The deformation gradient is split into elastoplastic and viscoelastic components, each contributing differently to the overall stress.

Elastoplastic Component

This component models material behavior using the standard Cauchy stress tensor derived from a fixed corotated model. Elastoplastic strain updates are computed through deformation gradients influenced by the internal velocity field.

Viscoelastic Component

The viscoelastic model incorporates time-dependent deformation, enhancing the realism of simulated interactions. Stress in this component arises from singular value-based tensor calculations, with viscosity parameters controlling energy dissipation.

Score Distillation Sampling Optimization

Physics3D employs Score Distillation Sampling (SDS) to optimize physical parameters. This technology adapts video diffusion models to derive accurate physical priors, making the simulation realistic. SDS calculates gradients using a variance-weighted approach, refining physical estimates derived from rendered Gaussian sequences.

Experimental Results

Qualitative and Quantitative Evaluations

Physics3D demonstrates superior performance in generating accurate, physically consistent animations compared to contemporary models such as PhysDreamer and PhysGaussian.

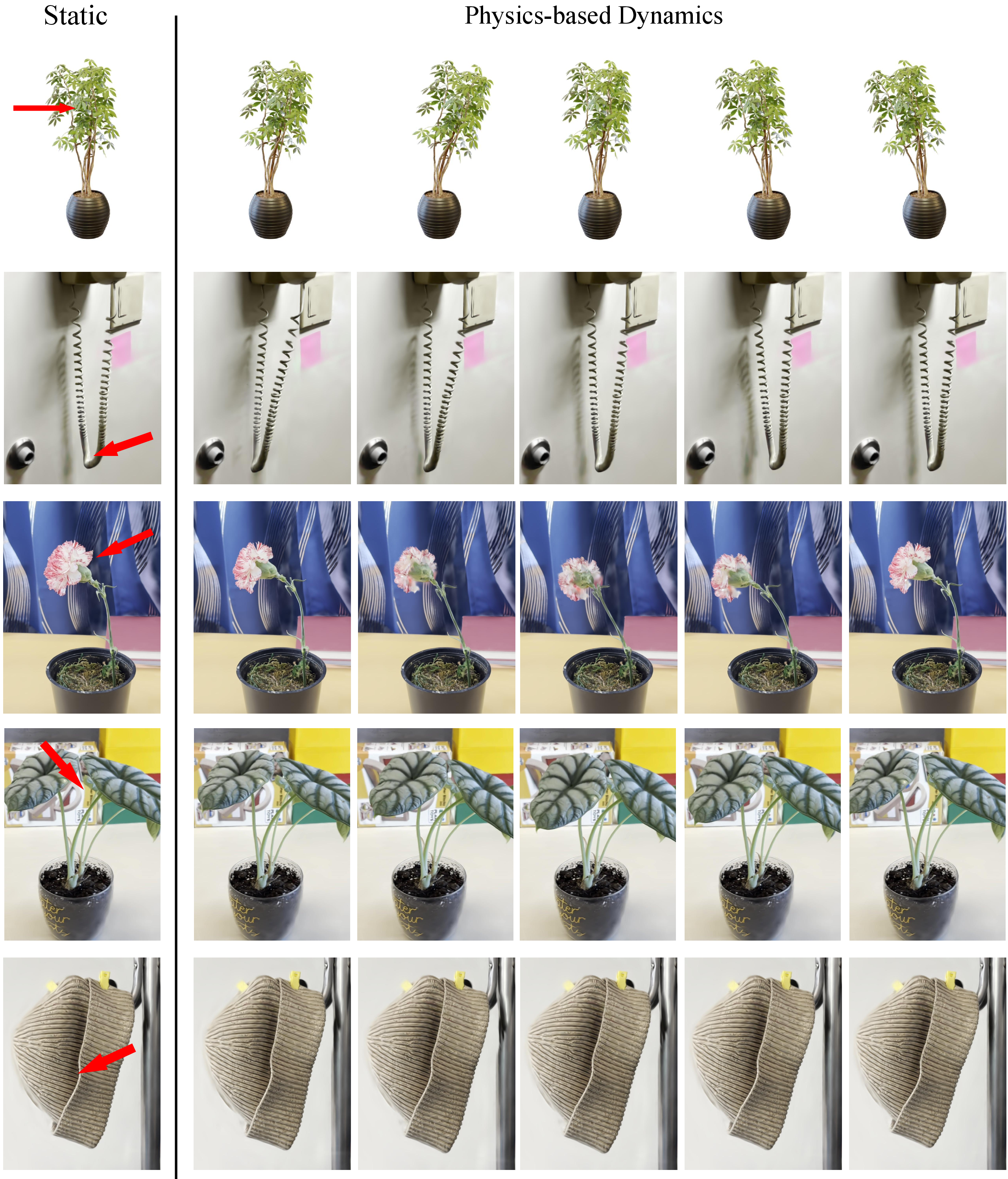

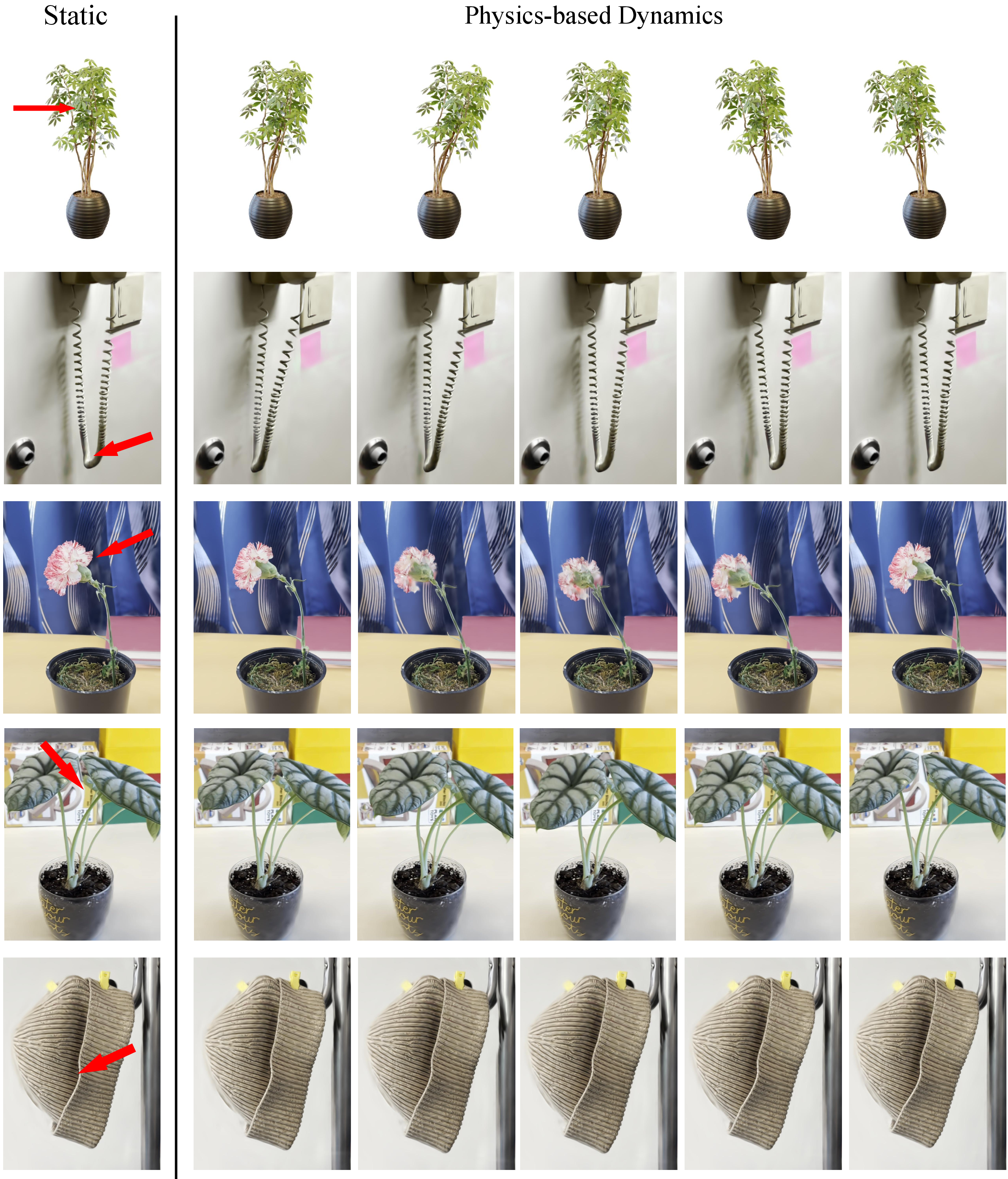

Figure 3: Visual results of Physics3D on different subjects with an external force (red arrow). Physics3D generates realistic scene movements with good motion consistency.

Quantitative metrics, including PSNR, SSIM, MS-SSIM, and VMAF, underscore its superior video quality and fidelity.

Ablation Studies

Ablation studies highlight the necessity of both the elastoplastic and viscoelastic components. Removing either results in noticeable degradation of the simulation's physical realism, emphasizing their combined importance in capturing material dynamics.

Figure 4: Ablation study on elastoplastic and viscoelastic parts of our model.

Conclusion

Physics3D represents a significant advancement in the simulation of 3D object dynamics, bridging the gap between purely visual models and those incorporating comprehensive physical properties. The integration of a viscoelastic material model and video diffusion-derived optimization reflects a robust pathway toward realistic virtual environments. Future work may focus on reducing manual intervention by employing large-scale segmentation models for improved generalizability in complex scenarios. Physics3D heralds broader applications in realistic simulations and interactive media experiences.