Advanced Deep Operator Networks to Predict Multiphysics Solution Fields in Materials Processing and Additive Manufacturing (2403.14795v1)

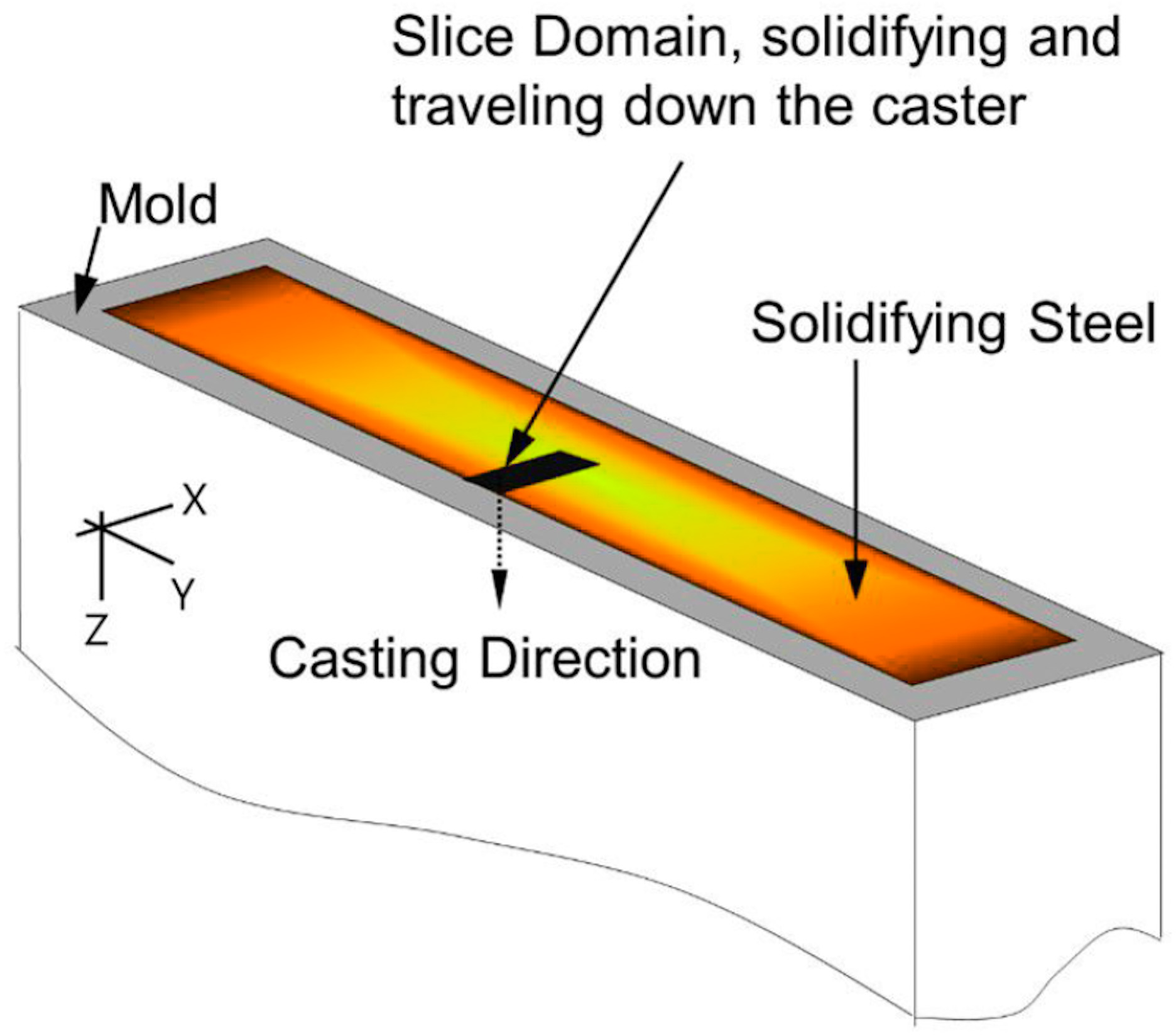

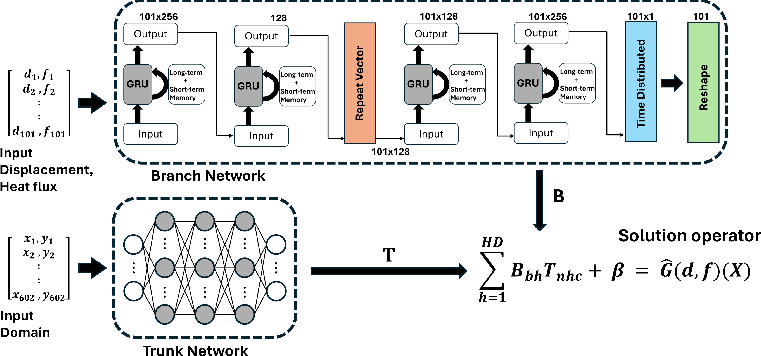

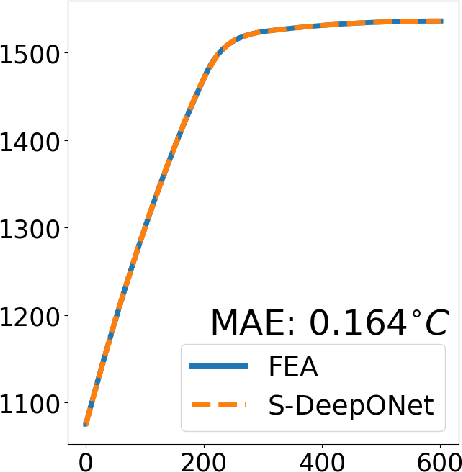

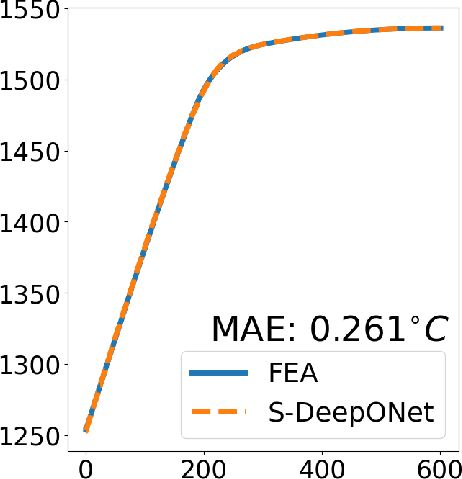

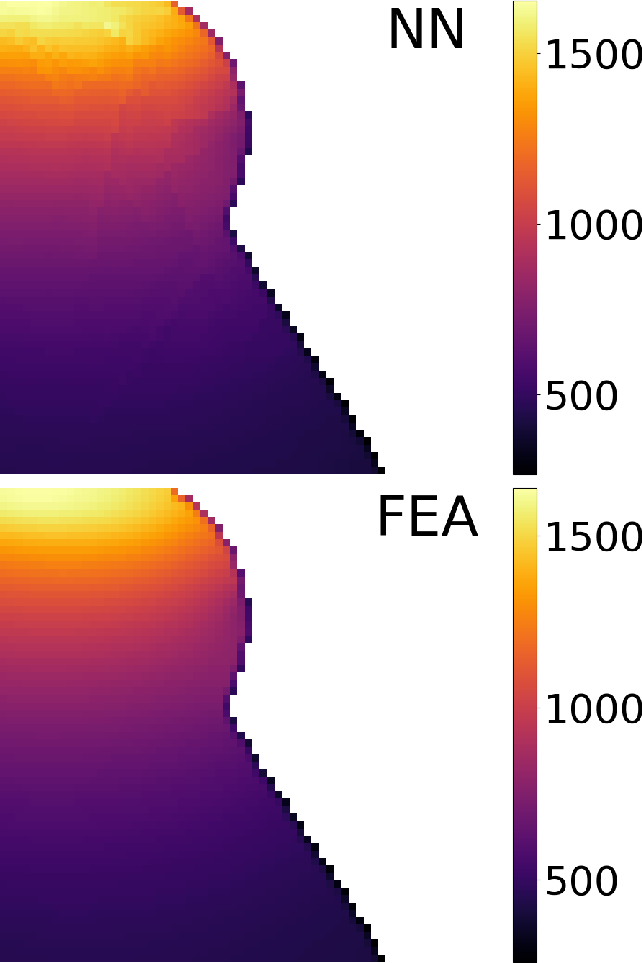

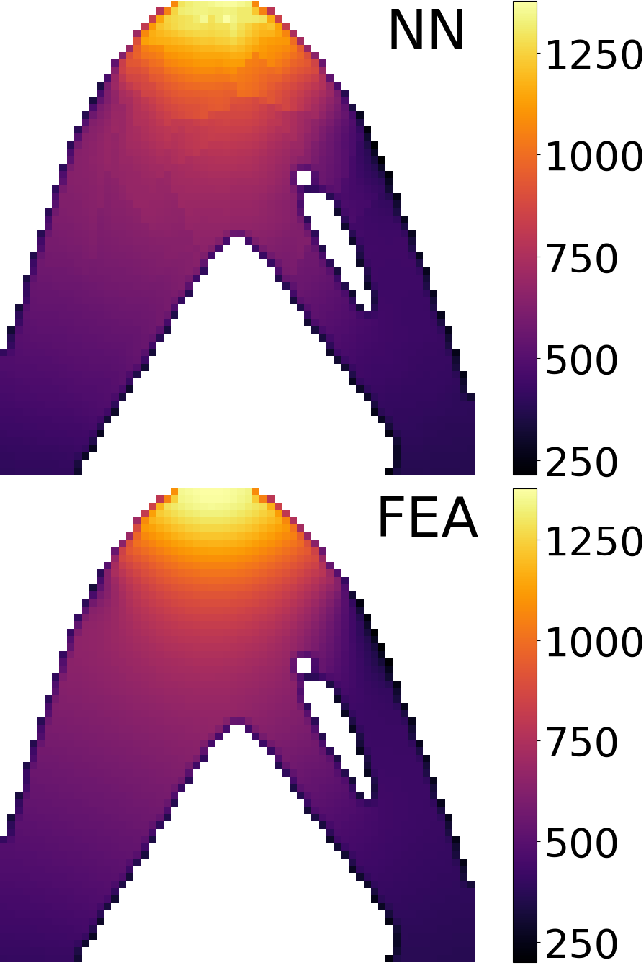

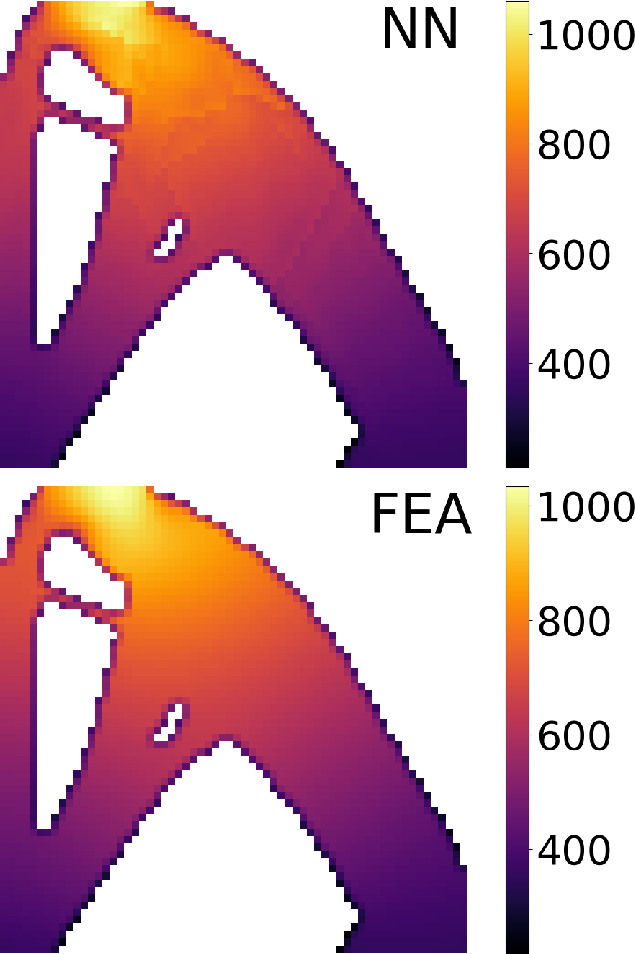

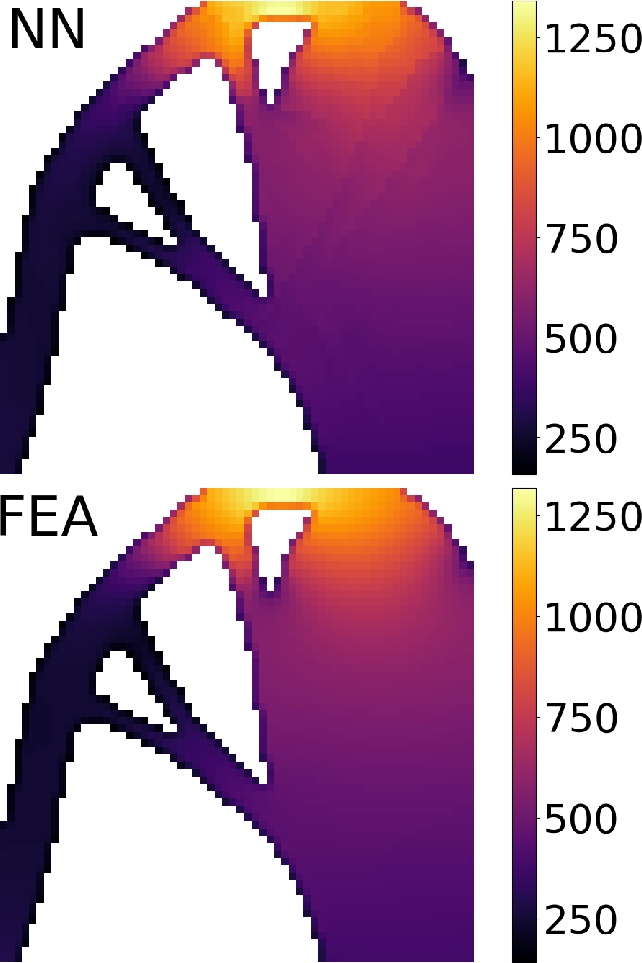

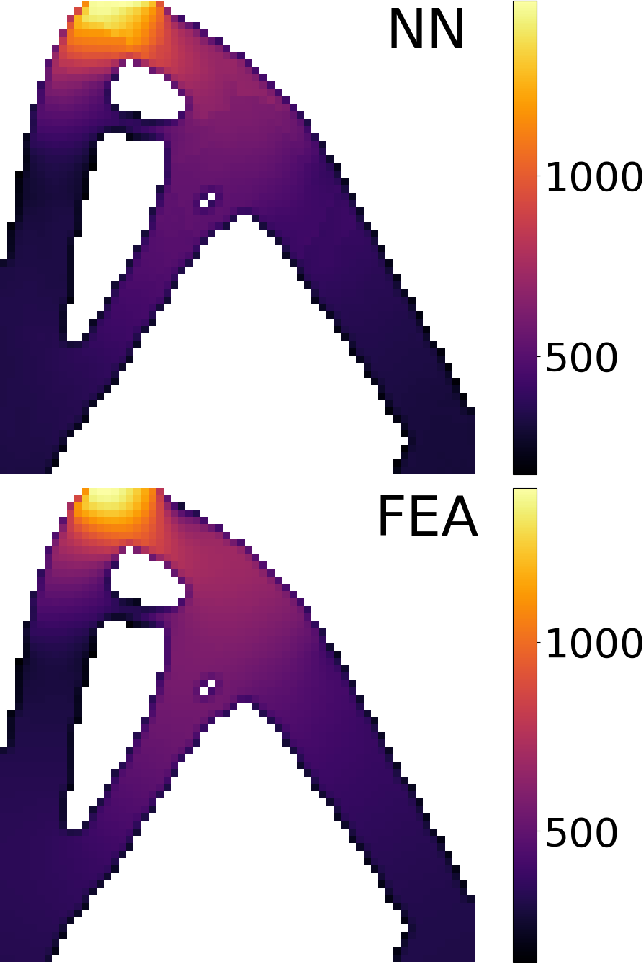

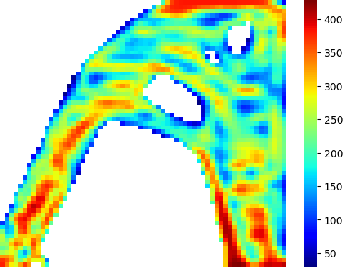

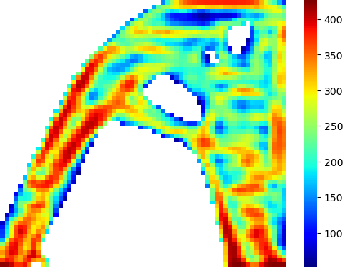

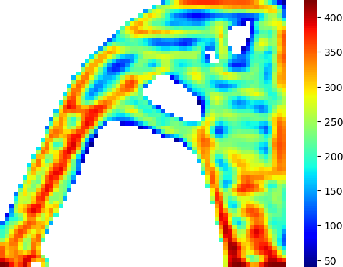

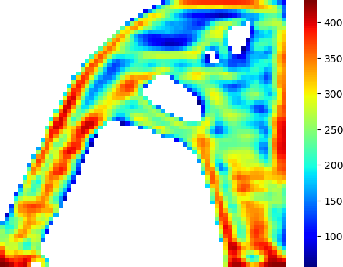

Abstract: Unlike classical artificial neural networks, which require retraining for each new set of parametric inputs, the Deep Operator Network (DeepONet), a lately introduced deep learning framework, approximates linear and nonlinear solution operators by taking parametric functions (infinite-dimensional objects) as inputs and mapping them to complete solution fields. In this paper, two newly devised DeepONet formulations with sequential learning and Residual U-Net (ResUNet) architectures are trained for the first time to simultaneously predict complete thermal and mechanical solution fields under variable loading, loading histories, process parameters, and even variable geometries. Two real-world applications are demonstrated: 1- coupled thermo-mechanical analysis of steel continuous casting with multiple visco-plastic constitutive laws and 2- sequentially coupled direct energy deposition for additive manufacturing. Despite highly challenging spatially variable target stress distributions, DeepONets can infer reasonably accurate full-field temperature and stress solutions several orders of magnitude faster than traditional and highly optimized finite-element analysis (FEA), even when FEA simulations are run on the latest high-performance computing platforms. The proposed DeepONet model's ability to provide field predictions almost instantly for unseen input parameters opens the door for future preliminary evaluation and design optimization of these vital industrial processes.

- World Steel Association . World steel in figures 2023, 2023. https://worldsteel.org/steel-topics/statistics/world-steel-in-figures-2023/.

- Directed energy deposition additive manufacturing of functionally graded al-w composites. Additive Manufacturing, 39:101845, 2021.

- On the design optimisation of direct energy deposited support structures to repair aero-engine turbine segments. Additive Manufacturing, 56:102905, 2022.

- Additive manufacturing for the aerospace industry. Elsevier, 2019.

- In-situ monitoring of melt pool images for porosity prediction in directed energy deposition processes. IISE Transactions, 51(5):437–455, 2019.

- Thermal histories and microstructures in direct energy deposition of a high speed steel thick deposit. Materials Letters, 236:42–45, 2019.

- Advances in additive manufacturing process simulation: Residual stresses and distortion predictions in complex metallic components. Materials & design, 193:108779, 2020.

- Simulation of powder bed metal additive manufacturing microstructures with coupled finite difference-monte carlo method. Additive Manufacturing, 41:101953, 2021.

- Simulation and experimental comparison of the thermo-mechanical history and 3d microstructure evolution of 304l stainless steel tubes manufactured using lens. Computational Mechanics, 61:559–574, 2018.

- Modeling and simulation of microstructure evolution for additive manufacturing of metals: a critical review. Metallurgical and Materials Transactions A, 51:4970–4983, 2020.

- Mesoscopic simulation model of selective laser melting of stainless steel powder. Journal of Materials Processing Technology, 214(11):2627–2636, 2014.

- Laser powder bed fusion additive manufacturing of metals; physics, computational, and materials challenges. Applied Physics Reviews, 2(4), 2015.

- Yi Zhang and Junyan He. Additive manufacturing material behavior prediction-a simulation based icme approach. In AIAA SCITECH 2023 Forum, page 2080, 2023.

- A numerical investigation on the physical mechanisms of single track defects in selective laser melting. International Journal of Heat and Mass Transfer, 126:957–968, 2018.

- Efficient thermo-mechanical model for solidification processes. International journal for numerical methods in engineering, 66(12):1955–1989, 2006.

- Multiphysics model of metal solidification on the continuum level. Numerical Heat Transfer, Part B: Fundamentals, 58(6):371–392, 2010a.

- Implementation of a thermomechanical model for the simulation of selective laser melting. Computational Mechanics, 54(1):33–51, 2014.

- Understanding the effect of laser scan strategy on residual stress in selective laser melting through thermo-mechanical simulation. Additive Manufacturing, 12:1–15, 2016.

- Thermomechanical model development and in situ experimental validation of the laser powder-bed fusion process. Additive Manufacturing, 16:73–80, 2017.

- Numerical investigation of residual stresses in thin-walled additively manufactured structures from selective laser melting. Heliyon, 9(9):e19385, 2023.

- A review of multi-scale and multi-physics simulations of metal additive manufacturing processes with focus on modeling strategies. Additive Manufacturing, 47:102278, 2021.

- Enhanced latent heat method to incorporate superheat effects into fixed-grid multiphysics simulations. Numerical Heat Transfer, Part B: Fundamentals, 57(6):396–413, 2010b.

- Multiphysics modeling of continuous casting of stainless steel. Journal of Materials Processing Technology, 278:116469, 2020.

- Temporally continuous thermofluidic–thermomechanical modeling framework for metal additive manufacturing. International Journal of Mechanical Sciences, 254:108424, 2023.

- Multiphysics simulations: Challenges and opportunities. The International Journal of High Performance Computing Applications, 27(1):4–83, 2013.

- Holistic computational design within additive manufacturing through topology optimization combined with multiphysics multi-scale materials and process modelling. Progress in Materials Science, page 101129, 2023.

- Audio-visual speech recognition using deep learning. Applied intelligence, 42:722–737, 2015.

- A survey of deep learning techniques for autonomous driving. Journal of field robotics, 37(3):362–386, 2020.

- Designing impact-resistant bio-inspired low-porosity structures using neural networks. Journal of Materials Research and Technology, 27:767–779, 2023.

- Integrating physics-based modeling with machine learning for lithium-ion batteries. Applied Energy, 329:120289, 2023.

- Physics-informed deep learning for simultaneous surrogate modeling and pde-constrained optimization of an airfoil geometry. Computer Methods in Applied Mechanics and Engineering, 411:116042, 2023.

- Robust deep learning-based diagnosis of mixed faults in rotating machinery. IEEE/ASME Transactions on Mechatronics, 25(5):2167–2176, 2020. doi: 10.1109/TMECH.2020.3007441.

- Surrogate neural network model for sensitivity analysis and uncertainty quantification of the mechanical behavior in the optical lens-barrel assembly. Computers & Structures, 270:106843, 2022.

- Machine learning in additive manufacturing: a review. Jom, 72:2363–2377, 2020.

- Machine learning for advanced additive manufacturing. Matter, 3(5):1541–1556, 2020.

- Deep learning sequence methods in multiphysics modeling of steel solidification. Metals, 11(3):494, 2021.

- Temporal convolutional networks for data-driven thermal modeling of directed energy deposition. Journal of Manufacturing Processes, 85:405–416, 2023.

- A physics-informed machine learning method for predicting grain structure characteristics in directed energy deposition. Computational Materials Science, 202:110958, 2022.

- Metallurgy, mechanistic models and machine learning in metal printing. Nature Reviews Materials, 6:48–68, 2021.

- Accelerating phase-field simulation of three-dimensional microstructure evolution in laser powder bed fusion with composable machine learning predictions. Additive Manufacturing, 79:103938, 2024.

- Learning nonlinear operators via deeponet based on the universal approximation theorem of operators. Nature machine intelligence, 3(3):218–229, 2021a.

- Deep learning operator network for plastic deformation with variable loads and material properties. Engineering with Computers, pages 1–13, 2023.

- A physics-informed variational deeponet for predicting crack path in quasi-brittle materials. Computer Methods in Applied Mechanics and Engineering, 391:114587, 2022.

- Learning mappings from iced airfoils to aerodynamic coefficients using a deep operator network. Journal of Aerospace Engineering, 36(5):04023035, 2023.

- Training a deep operator network as a surrogate solver for two-dimensional parabolic-equation models. The Journal of the Acoustical Society of America, 154(5):3276–3284, 2023.

- En-deeponet: An enrichment approach for enhancing the expressivity of neural operators with applications to seismology. Computer Methods in Applied Mechanics and Engineering, 420:116681, 2024.

- Improved generalization with deep neural operators for engineering systems: Path towards digital twin. Engineering Applications of Artificial Intelligence, 131:107844, 2024.

- Deep operator learning-based surrogate models with uncertainty quantification for optimizing internal cooling channel rib profiles. International Journal of Heat and Mass Transfer, 219:124813, 2024.

- Data-driven and physics-informed deep learning operators for solution of heat conduction equation with parametric heat source. International Journal of Heat and Mass Transfer, 203:123809, 2023.

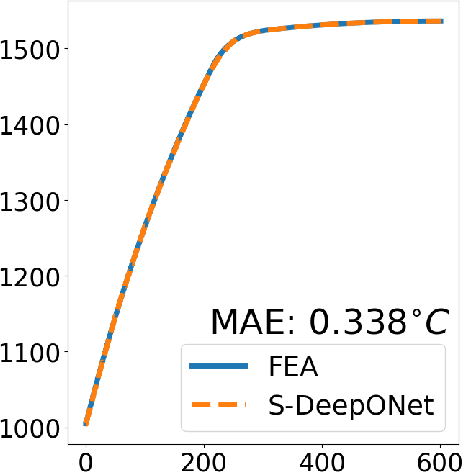

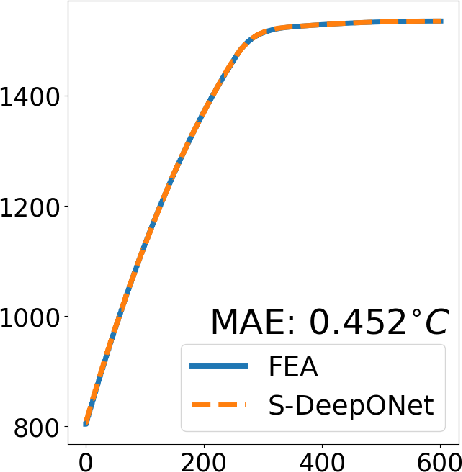

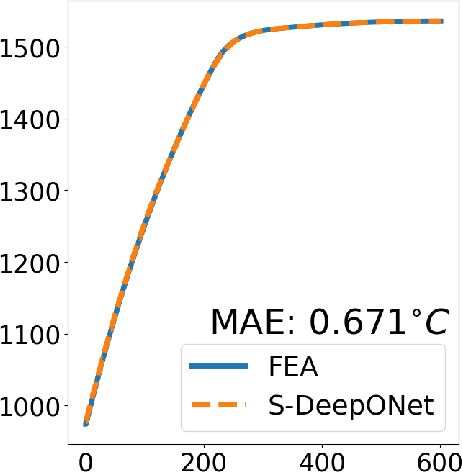

- Sequential deep operator networks (s-deeponet) for predicting full-field solutions under time-dependent loads. Engineering Applications of Artificial Intelligence, 127:107258, 2024.

- Novel deeponet architecture to predict stresses in elastoplastic structures with variable complex geometries and loads. Computer Methods in Applied Mechanics and Engineering, 415:116277, 2023a. ISSN 0045-7825. doi: https://doi.org/10.1016/j.cma.2023.116277. URL https://www.sciencedirect.com/science/article/pii/S0045782523004012.

- Fast and accurate reduced-order modeling of a moose-based additive manufacturing model with operator learning. The International Journal of Advanced Manufacturing Technology, 129(7):3123–3139, 2023.

- Fourier neural operator for parametric partial differential equations. arXiv preprint arXiv:2010.08895, 2020.

- Simple constitutive equations for steel at high temperature. Metallurgical Transactions A, 23:903–918, 1992.

- Hong Zhu. Coupled thermo-mechanical finite-element model with application to initial solidification. PhD thesis, The University of Illinois at Urbana-Champaign Urbana, IL, USA, 1996.

- SIMULIA Dassault Systèmes. Abaqus/standard user’s manual version 2022, 2022.

- DASSAULT SYSTEMES. Special-purpose techniques for additive manufacturing. https://docs.software.vt.edu/abaqusv2022/English/?show=SIMACAEANLRefMap/simaanl-m-AMSpecialPurpose-sb.htm, 2022a. [Online; accessed 04-March-2024].

- Special Metals. Inconel Alloy 625. https://https://www.specialmetals.com/documents/technical-bulletins/inconel/inconel-alloy-625.pdf. [Online; accessed 04-March-2024].

- Effect of inter-layer dwell time on distortion and residual stress in additive manufacturing of titanium and nickel alloys. Journal of Materials Processing Technology, 215:123–131, 2015.

- Size-dependence of am ti–6al–4v: Experimental characterization and applications in thin-walled structures simulations. Thin-Walled Structures, 187:110722, 2023b.

- Effects of size, geometry, and testing temperature on additively manufactured ti-6al-4v titanium alloy. Additive Manufacturing, 80:103970, 2024.

- A new finite element model for welding heat sources. Metallurgical transactions B, 15:299–305, 1984.

- Residual strain predictions for a powder bed fusion inconel 625 single cantilever part. Integrating Materials and Manufacturing Innovation, 8:294–304, 2019.

- DASSAULT SYSTEMES. Thermomechanical analysis of FDM- and LDED-type additive manufacturing processes. https://https://docs.software.vt.edu/abaqusv2022/English/?show=SIMACAEANLRefMap/simaanl-c-amspecialpurpose-lded.htm, 2022b. [Online; accessed 10-March-2024].

- Deepxde: A deep learning library for solving differential equations. SIAM review, 63(1):208–228, 2021b.

- Adam: A method for stochastic optimization. arXiv preprint arXiv:1412.6980, 2014.

- Resunet-a: A deep learning framework for semantic segmentation of remotely sensed data. ISPRS Journal of Photogrammetry and Remote Sensing, 162:94–114, 2020.

- Improved architectures and training algorithms for deep operator networks. Journal of Scientific Computing, 92(2):35, 2022.

- Sensitivity analysis using the metamodel of optimal prognosis. Weimar Optimization and Stochastic Days, 8(0), 2011.

Sponsor

Paper Prompts

Sign up for free to create and run prompts on this paper using GPT-5.

Top Community Prompts

Collections

Sign up for free to add this paper to one or more collections.