- The paper introduces a scalable soft robotic arm (SoPrA) that uses fiber-reinforced actuators and integrated flex sensors to achieve precise motion and force estimation.

- It employs a piecewise constant curvature model enhanced with augmented rigid body dynamics to balance model accuracy and real-time performance.

- Experimental validation demonstrates an average tip position error of 1.96cm and effective external force estimation in obstructed settings.

SoPrA: A Scalable Soft Continuum Robotic Arm with Proprioceptive Sensing

This essay discusses the design and analytical modeling of a Soft continuum Proprioceptive Arm (SoPrA), which integrates proprioceptive sensing for enhanced manipulation and locomotion in real-world environments. The SoPrA design incorporates fiber-reinforced fluidic elastomer actuators and an internal capacitive flex sensor, enabling accurate motion modeling and external force estimation without external sensors. The arm's dynamic model considers inertial effects, material properties, and proprioceptive sensor data, validated through experiments demonstrating accuracy in estimation and force sensing in obstructed environments.

Design and Fabrication of SoPrA

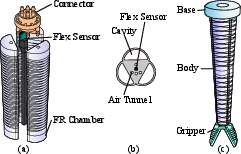

The SoPrA design is based on fiber-reinforced soft pneumatic actuators and a pleated soft pneumatic gripper (Figure 1). The arm is fabricated by combining individual fiber-reinforced chambers into segments and integrating proprioceptive sensors and pneumatic connectors.

Figure 1: Overview of the assembly process, showing the combination of fiber-reinforced chambers with a flex sensor to form a segment, and the integration of segments with connectors and a gripper.

The tapered cross-section of each segment provides advantages in fabrication and actuation. It simplifies silicone body extraction from 3D-printed molds and optimizes torque allocation by positioning larger segments near the base. This design is geometrically scalable, allowing for different sizes and DOF while maintaining consistent fabrication methods.

Analytical Modeling Framework

The arm's shape is modeled using piecewise constant curvature (PCC) elements for real-time dynamic behavior prediction. The dynamic model accounts for chamber pressures, external forces, inertial matrix, Coriolis and centripetal forces, gravity, stiffness, and damping, as shown in the equation:

Ap+JTf=B(q)q¨+c(q,q˙)+g(q)+Kq+Dq˙

Here, A converts chamber pressures to generalized forces, J is the Jacobian, f is the external force, p is the air pressure vector, and q represents the robot's pose. The model uses an augmented rigid body approach to calculate kinetic elements and an analytical model to derive stiffness and damping matrices from elastomer stress.

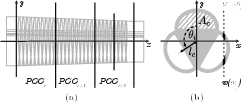

Figure 2: Subsections and cross section showing the piecewise constant curvature (PCC) elements and cross-sectional parameters used in the analytical model.

The number of PCC elements balances model accuracy and complexity, achieving sufficient precision while maintaining real-time performance. The material properties are characterized experimentally to determine coefficients for elastic and drag forces.

Proprioceptive Sensing and Force Estimation

SoPrA integrates a 2-axis digital flex sensor for proprioceptive measurements, enabling contact state estimation without external motion capture systems. The sensor measures bending angles, providing a linear relationship between the soft robot's pose q and sensor measurement s:

s=Sq

The sensor data, combined with the dynamic model, facilitates the estimation of external contact forces by solving a quadratic program. This approach optimizes the robot's pose to accurately explain sensor measurements, improving model error and estimating external forces at the tip.

Figure 3: External load estimation experiment illustrating the objects grasped and the arm poses with their estimation results.

Experimental Validation

Experiments were conducted on a two-segment SoPrA configuration to validate the accuracy of the dynamic model and the effectiveness of proprioceptive measurements for external load estimation. Results demonstrated that the model accurately predicts tip position during feedforward actuation, with an average error of \SI{1.96}{\centi\meter}. Additionally, the arm could estimate external loads by integrating flex sensor measurements with the dynamic model, showing a linear relationship between actual and estimated weights.

Discussion and Conclusion

The integration of fiber reinforcement and proprioceptive sensors enables SoPrA to achieve accurate motion modeling and external force estimation. Increasing the number of PCC elements enhances model accuracy, while the augmented rigid body model simplifies kinematic and dynamic calculations. The experimental results validate SoPrA's capabilities in continuous motion and proprioception, demonstrating its potential for manipulation tasks in obstructed environments. Future work will focus on improving model formulation, exploring additional proprioceptive modes, and applying SoPrA to practical tasks in everyday settings, contributing to advancements in soft robot design and control.